Design and production of technologies

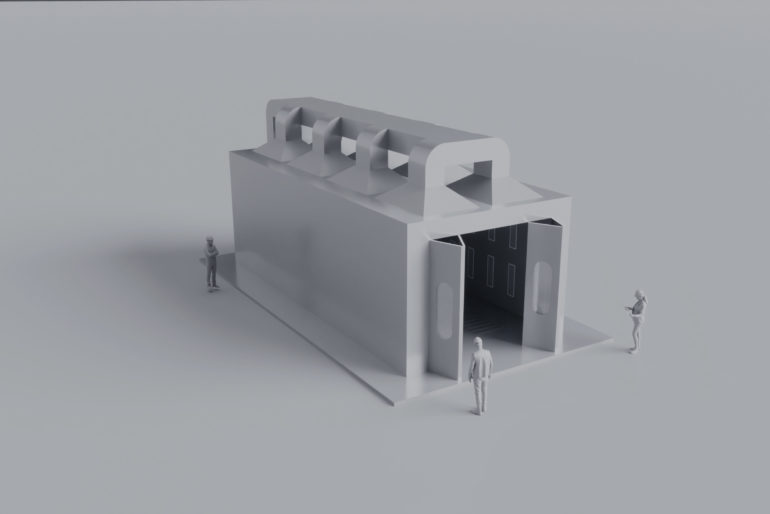

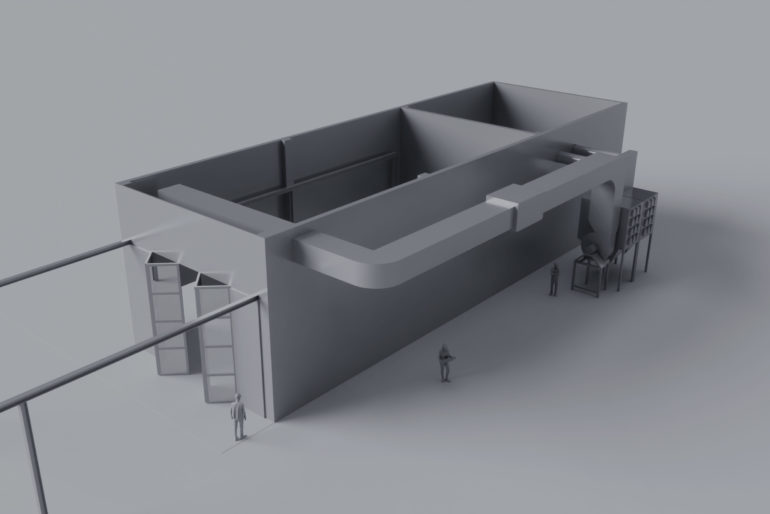

Blasting boxes Blasting equipment Paint shops and drying boxes Metallization Filtration technology Containers Compressed air preparationBlasting boxes

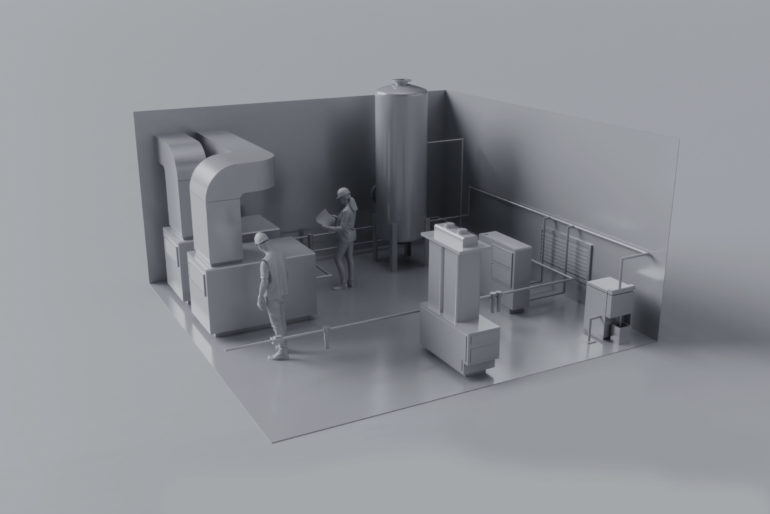

We make individual designs of blasting boxes according to specific customer needs. The blast box technology can be designed for one or more blasters with the ability to control the blast flow according to the type of base material being blasted and the type of abrasive used. We will propose the most suitable technology to the customer, which will provide the best ratio between investment and operating costs. Together with the design and installation, we also provide follow-up service of the technology to ensure long-term reliability of the technology.

Blasting equipment

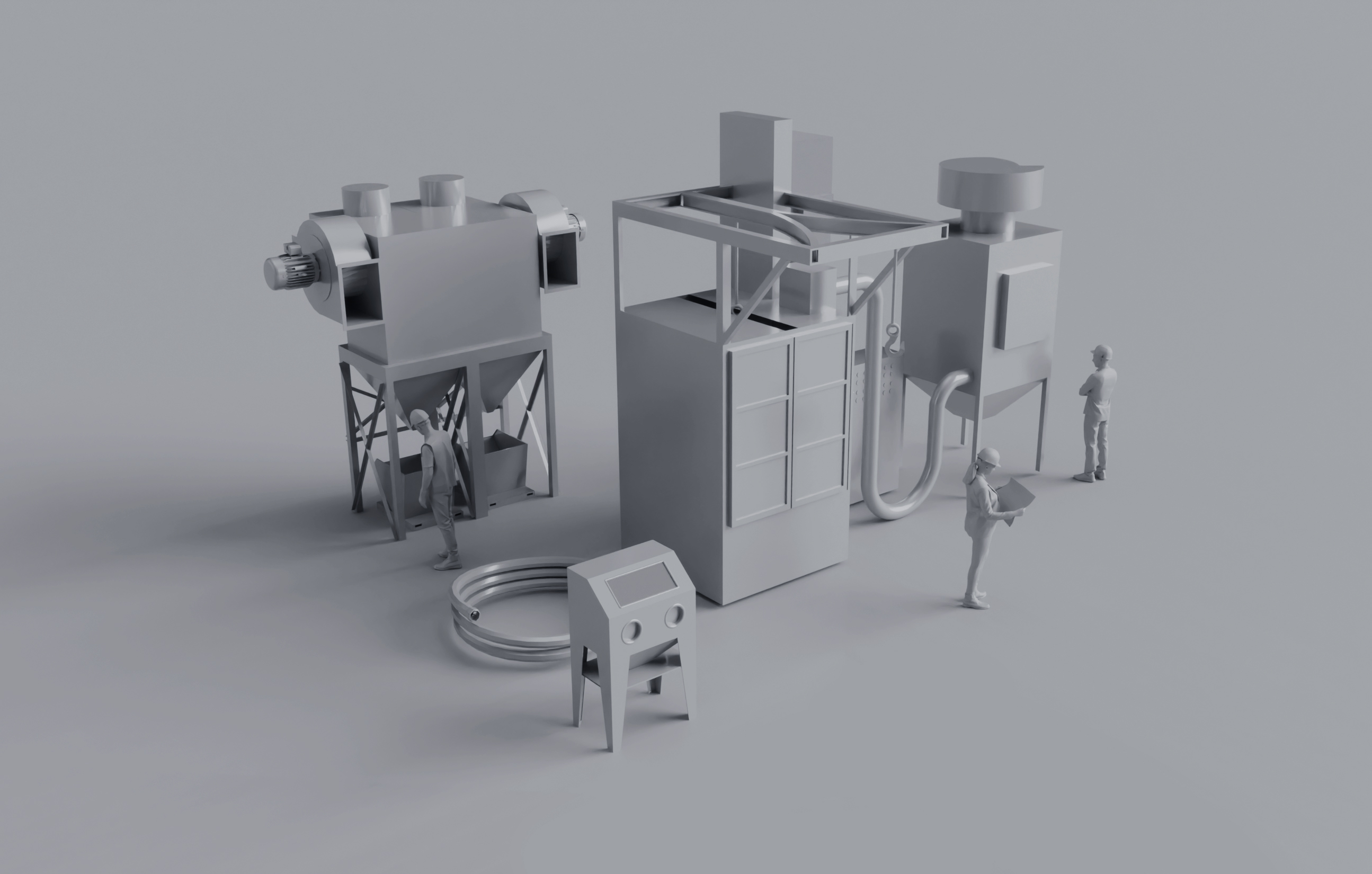

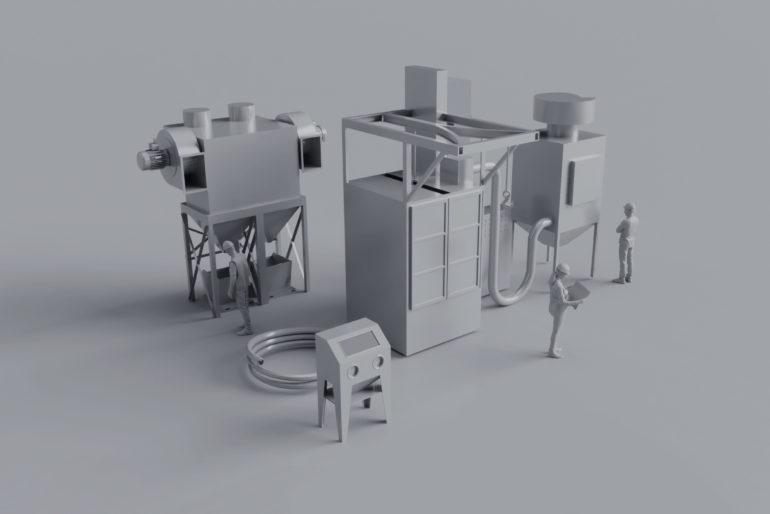

We design and manufacture our own technology components and blasting equipment. We cooperate with renowned manufacturers of blasting equipment. For specific customer requirements, we can design blasting equipment for automatic blasting operation as well as equipment for manual blasting by an operator/blasting machine. Together with the blasting technology, we will supply you with a complete accessory technology including warehouse and spare parts supply.

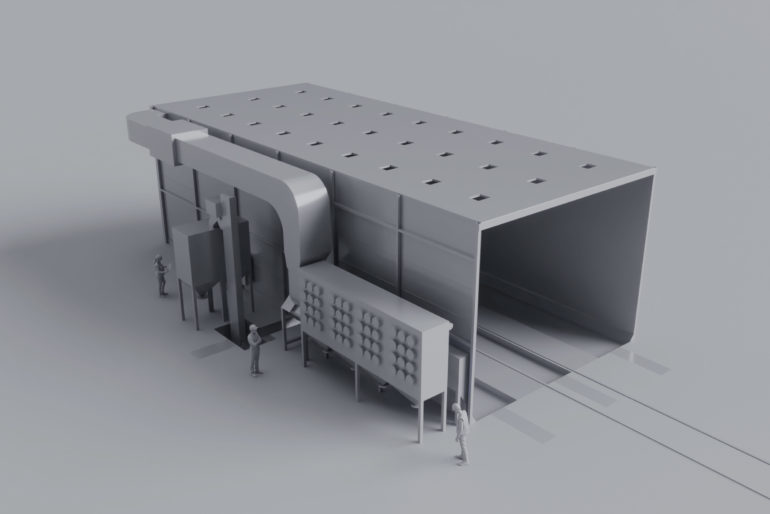

Paint shops and drying boxes

We make individual designs of paint booths according to the customer’s specific needs. We can design and implement a complete project of paint shop and drying box technology for our customers. In addition to the complete turnkey supply of paint shops, we can offer and supply technological application equipment, both high and low pressure, for the application of coatings. Our corrosion engineers can suggest the appropriate surface treatment for the specific type and application of the final painted product, as well as the appropriate choice of coatings to ensure the highest quality finish for your products. Along with the design and installation, we also service the technology to ensure long-term reliability.

Metallization

We provide individual designs of metallization boxes according to the customer’s specific needs. For specific customer requirements we can design metallization boxes for hot-dip coating: Zinc, Aluminium, Zinacor (zinc-aluminium alloy, most commonly ZnAl15).

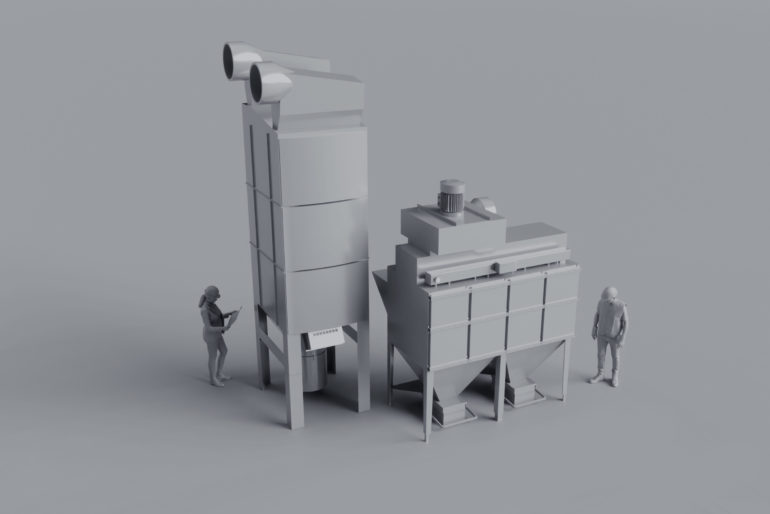

Filtration technology

We design and supply suitable filtration units for paint and blasting technologies, both for the capture of dust particles and for the capture of volatile organic compounds (VOCs). Dust generated during blasting, grinding, cutting, etc. is sucked into the filter unit by a fan that is part of the filter unit. The dust contained in the intake air is spread over the entire surface of the filter inserts in the filter. Only clean, particulate-free gas can flow through the filter cartridge. Solid dust particles adhere to the outer parts of the filter cartridges, which are regenerated by pressurized air. After regeneration, the solid particles from the filter inserts fall into the hopper, where they fall by gravity into the dust collection bag. In the case of paint shops, organic volatiles are released during the application of paints and need to be captured during the extraction of air from the paint booth. The first stage of colour particle capture takes place at the first stage of filtration, which can be polyester or glass fibre filters. Filter cartridges filled with activated carbon, which absorbs volatile organic compounds (VOCs), can be installed in the next filtration stages.

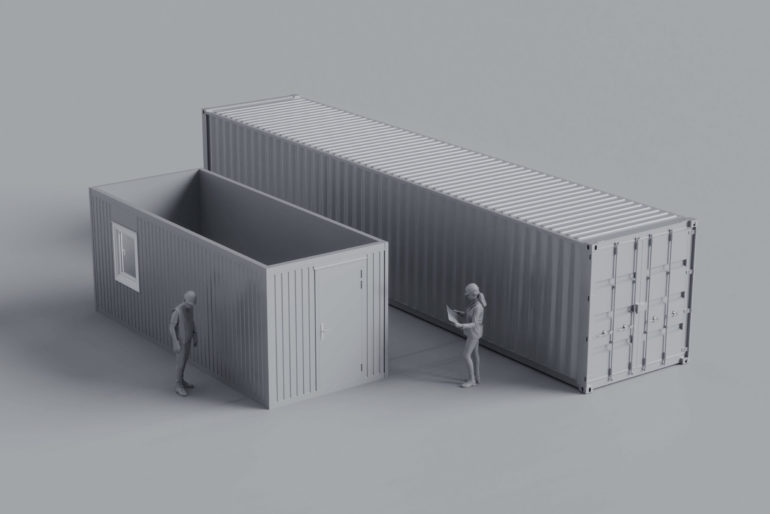

Containers

We use shipping containers in the sizes 20′ / 20’HC and 40′ / 40’HC, which are the optimal solution for storage or office space. We use containers for mobile painting, blasting technologies.

Compressed air preparation

The preparation and supply of compressed air with the appropriate parameters is essential for the operation of the blasting and painting box technology. That is why we specify the necessary air pressure parameters together with the design of the technology, or design suitable turnkey compressor stations. We design the compressor station assembly to be efficient for the operation.